save money

- Lower chemical usage

- Choose you own, compatible pre-dip chemical

- Reduced towel and laundry cost

increase profit

- Faster, consistent prep.

- Better stimulation for let down

low operating cost

- Wear part costs as low as $0.96/cow/month

- Less then 1 oz. of mixed chemical per cow

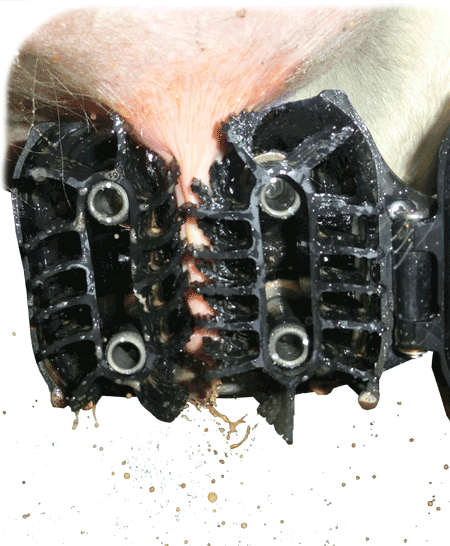

Outperforms all others for superior cleaning and stimulation

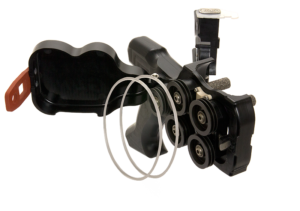

• Exclusive elastomer teat belts use flaps to contact and conform to each teat.

• The belts auto adjust to size and shape of teat.

• Teat end is cleaned when entering and exiting teat belts.

• As the teat belt flaps rotate around the lower shaft, they accelerate to flick off water and debris.

• Water/ chemical mixture sprayed onto belts and teat at 6 oz./min.

• 2 stage trigger allows the operator to turn off liquid and keep belts moving to partially dry off teats.

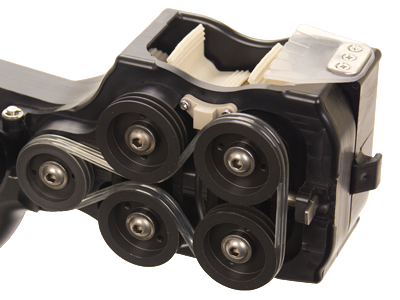

Quick No Tool Disassembly

• Exclusive teat belt design

• More complete teat coverage

• Auto adjusts to teat size

• Excellent stimulation

• Quick and thorough cleaning

• Air driven

Teat Belt Features

Elastomer Teat Belts for long life, even when using sand bedding.

• Ribs on flaps provide fast cleaning and greater stimulation.

• Segmented, overlapping flaps that gently conform around the teat.

• Double ribbed flaps can be flipped for more life.

• Reversible belts for double the life.

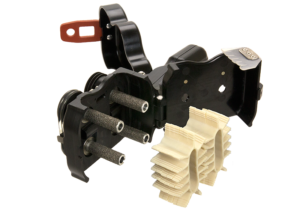

Drive System

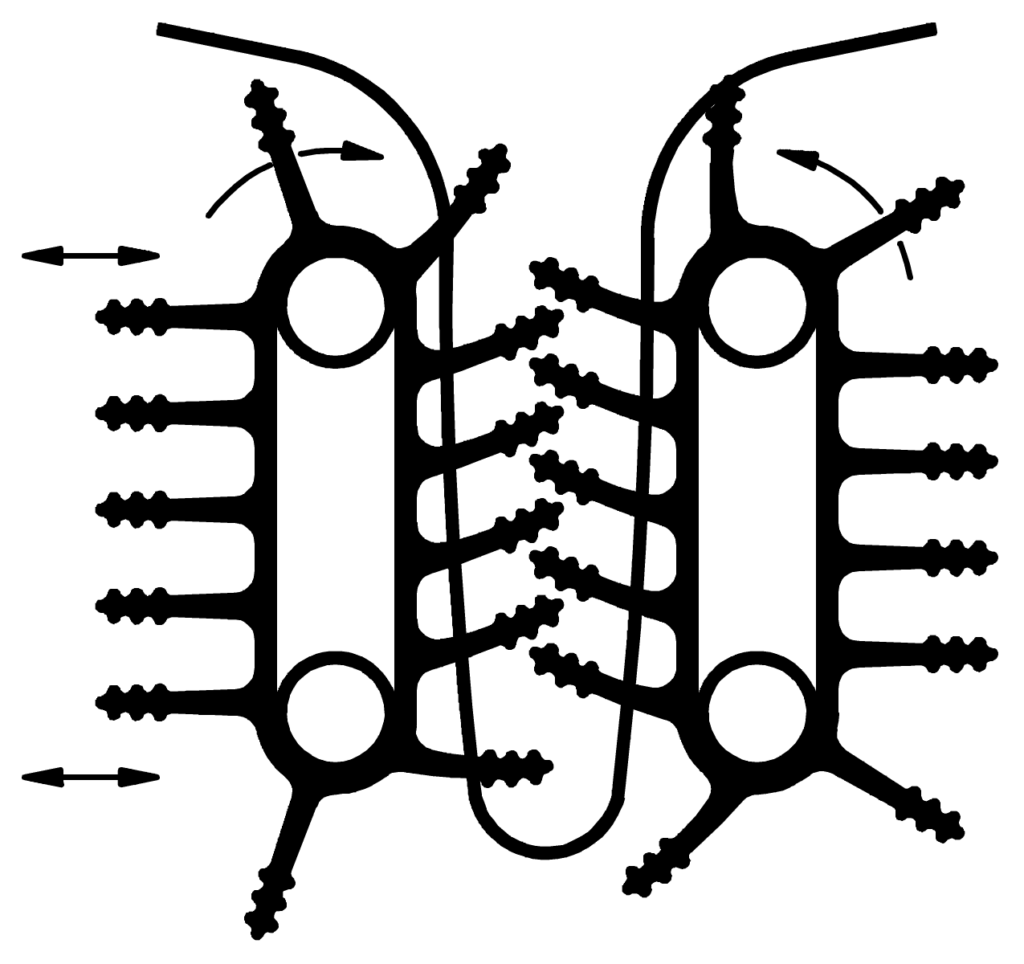

• Dual belts power all four spindles

• Drive belts also tension teat belts together adjusting for teat size and shape

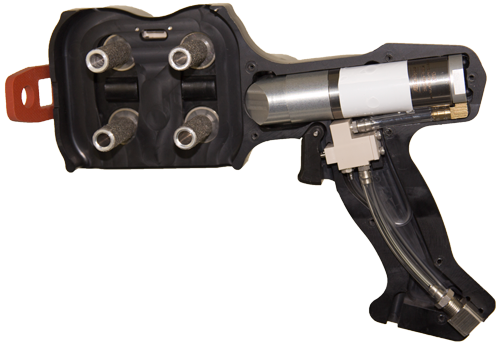

Inside The Udder Gun

• Powerful, compact Air motor

• Trigger operated air and water valve